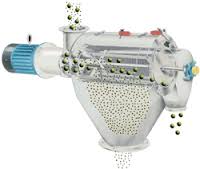

Centrifugal Screeners

Centrifugal Screeners are versatile, high capacity, compact and economical centrifugal sifter used for screening a wide variety of powders or granular materials, including chemicals, plastics and resins, foods, dairy products, pharmaceuticals and biologicals, at high rates. This equipment is the ideal choice for continuous scalping of dry or moist materials, even those that tend to ball or agglomerate as these units de-lump and de-agglomerate while screening.

Principles of Operation

Material is fed into the feed inlet and redirected into the cylindrical sifting chamber by means of a feed screw. Rotating, helical paddles within the chamber continuously propel the material against the screen, while the resultant, centrifugal force on the particles accelerates them through the apertures. These rotating paddles, which never make contact with the screen, also serve to breakup soft agglomerates. Over-sized particles and trash are ejected via the oversize discharge spout.

Features

- Quiet, vibration-free action

- Quick screen change: 2 minutes or less

- Easy clean-out

- Double seal outboard bearings

- Rapid sieving action

- Heavy duty construction for continuous operation

- Compact design

- Low power requirements

- Integral cleaning/ inspection door

Video