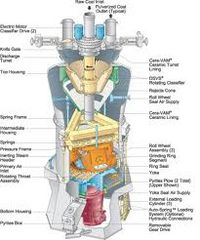

Coal Pulverizers

Coal Pulverizers are Pulverizers that are designed specifically for coals.

Operation Principles

Coal passes over the port opening and is swept upwards before it can be trapped in the interface between the rotating and stationary pieces. Older designed stationary airports require coal to travel over the interface where it can become trapped and cause wear.

The rotation of the ports reduces housing wear by spreading the wear more evenly over the entire periphery of the pulverizer. The 3-sided airport design results in a self-cleaning action of the gap area.

These new airports are two-piece rotating airports. The lower airport segment will be made of cast iron while the higher wear upper airport will be made of cast chrome-moly abrasion resistant white iron. The upper airport will be designed for the fuel and is a simple bolt on design and can be changed quickly as fuels change. This design extends the total wear life and as a result, reduces the required maintenance hours and extends the parts replacement cycle.

Features

- A raw coal feeder that regulates the coal flow from the coal bunker to the pulverizer

- A heat source that preheats the primary air for coal drying, either the boiler air heater or a steam-coil air heater

- A primary air fan that typically is located ahead of the pulverizer (pressurized mill) or after the pulverizer (suction mill)

- Piping that directs the coal and primary air from the pulverizer to the burners

- Burners that mix the coal and combustion air, both primary and secondary

Video