Difference between revisions of "Conveying Pipe Systems"

Jump to navigation

Jump to search

| Line 11: | Line 11: | ||

'''Conveying Pipe System''' is based on the construction of the conventional belt conveyor. Both fabric and as well as steel reinforcing can be used. However there are subtle differences between the two concepts.Conveying pipe systems is a modern and environmentally friendly transport system solving numerous problems associated with conventional conveyor system, i.e. spillage of materials, limitations with regard to steep incline and curve layout, etc. Conveying pipe systems also manages to transport difficult materials, i.e. powder and/or materials that are similar to liquid | '''Conveying Pipe System''' is based on the construction of the conventional belt conveyor. Both fabric and as well as steel reinforcing can be used. However there are subtle differences between the two concepts.Conveying pipe systems is a modern and environmentally friendly transport system solving numerous problems associated with conventional conveyor system, i.e. spillage of materials, limitations with regard to steep incline and curve layout, etc. Conveying pipe systems also manages to transport difficult materials, i.e. powder and/or materials that are similar to liquid | ||

Latest revision as of 11:42, 22 August 2012

Conveying Pipe System is based on the construction of the conventional belt conveyor. Both fabric and as well as steel reinforcing can be used. However there are subtle differences between the two concepts.Conveying pipe systems is a modern and environmentally friendly transport system solving numerous problems associated with conventional conveyor system, i.e. spillage of materials, limitations with regard to steep incline and curve layout, etc. Conveying pipe systems also manages to transport difficult materials, i.e. powder and/or materials that are similar to liquid

Features

- Dust and spillage free transportation

- Low noise emissions inclines up to 30°

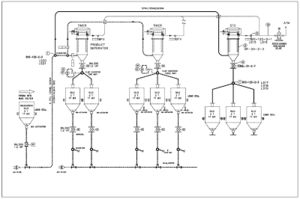

- Multiple feed and discharge points 8 km and more without transfer stations

- Simultaneous conveying of different materials in both directions

- Low power consumption

- Horizontal and vertical curves with radii to 45 metres