Difference between revisions of "Drum Cleaning Systems"

(Created page with "Category:Cleaning{{Knoppen}} <noinclude><!------------------------------------------------ * READ THIS FIRST * Only edit this page if you can improve the content. * Imprope...") |

|||

| Line 1: | Line 1: | ||

[[Category:Cleaning]]{{Knoppen}} | [[Category:Cleaning]]{{Knoppen}} | ||

[[File:Drum_Cleaning_Systems_01.jpg|thumb|right|Inside Drum Cleaning Systems]] | |||

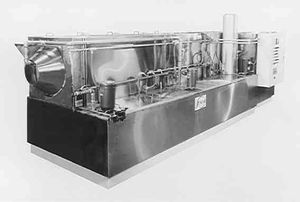

[[File:Drum_Cleaning_Systems_02.jpg|thumb|right|Large Drum Cleaning Systems]] | |||

The '''Drum Cleaning Systems''' are designed to clean larger containers including various sized 30 and 55 gallon drums, barrels, and overpaks, as well as handle small containers such as pails, buckets, jars, lids, and any other specialty parts contaminated with a wide variety of solvent or aqueous based materials. The Drum Washer and Crusher combination both feature corrosion resistant, high pressure pumps and spray nozzles which can remove even the most difficult residues from the containers. The high impingement jet spray technology can even eliminate cured resins and paints. A vapor tight lid is typically used to ensure vapor containment. Interlocked lid, secure sensors, and ground proving switches are standard features to ensure maximum operator safety. | |||

* | |||

* | |||

* | ==General features and options of an ideal Drum Cleaning System:== | ||

* - | *Washes Interior and Exterior Surfaces | ||

*Solvent, Caustic, Sanitizer, and Water washing | |||

*Explosion Resistant, ATEX, and Zone 0 models available | |||

*Electric or Pneumatically operated | |||

*Stainless or Carbon steel (Mild Steel) construction | |||

*Triple Rinse applications | |||

*Automated Drum Loading Systems | |||

*Nitrogen or CO2 Purging | |||

*Single, dual, tri, quad, and Conveyorized Configurations | |||

*Specialty wash racks | |||

*Exhaust system | |||

*Heated Drying | |||

*VOC Containment | |||

==Some additional features of Drum Cleaning Systems:== | |||

*Heated or Non-Heated built in sumps | |||

*Optional Lid Racks | |||

*Optional Multi-part racks | |||

*Conveyorized Options | |||

*Custom Door Options | |||

*Solvent Applications | |||

*Caustic Applications | |||

*Water Applications | |||

*Vapor Recovery | |||

==Video== | |||

<youtube>MGexKg9zpYk</youtube> | |||

Latest revision as of 07:11, 9 June 2013

The Drum Cleaning Systems are designed to clean larger containers including various sized 30 and 55 gallon drums, barrels, and overpaks, as well as handle small containers such as pails, buckets, jars, lids, and any other specialty parts contaminated with a wide variety of solvent or aqueous based materials. The Drum Washer and Crusher combination both feature corrosion resistant, high pressure pumps and spray nozzles which can remove even the most difficult residues from the containers. The high impingement jet spray technology can even eliminate cured resins and paints. A vapor tight lid is typically used to ensure vapor containment. Interlocked lid, secure sensors, and ground proving switches are standard features to ensure maximum operator safety.

General features and options of an ideal Drum Cleaning System:

- Washes Interior and Exterior Surfaces

- Solvent, Caustic, Sanitizer, and Water washing

- Explosion Resistant, ATEX, and Zone 0 models available

- Electric or Pneumatically operated

- Stainless or Carbon steel (Mild Steel) construction

- Triple Rinse applications

- Automated Drum Loading Systems

- Nitrogen or CO2 Purging

- Single, dual, tri, quad, and Conveyorized Configurations

- Specialty wash racks

- Exhaust system

- Heated Drying

- VOC Containment

Some additional features of Drum Cleaning Systems:

- Heated or Non-Heated built in sumps

- Optional Lid Racks

- Optional Multi-part racks

- Conveyorized Options

- Custom Door Options

- Solvent Applications

- Caustic Applications

- Water Applications

- Vapor Recovery

Video