Fill Pass Diverters

Jump to navigation

Jump to search

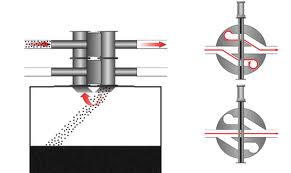

Fill Pass Diverter is specifically engineered to handle dry bulk solids in vacuum or dilute phase pneumatic conveying systems with pressures up to 15 psig (1 barg) depending on size. It provides a versatile and reliable solution for filling one or more in-line weigh hoppers when material is conveyed pneumatically through a closed loop system. The design of the fill pass diverter utilizes spread hopper inlet or outlet stacks for improved air and material separation reducing fill time and down line material carryover.

Applications

- Designed for vacuum or dilute phase pneumatic conveying

- Handles nonabrasive powders, granular or pellets

- Unique stackable Valve Design

- Key Industries Served:

- Agriculture

- Chemicals

- Foods

- Minerals

- Petrochemicals,

- Plastics

- Textiles

Features

- The fill pass diverter is designed with seal plates that are shielded from blast abrasion allowing the diverter to positively seal air and material over its service life. Ordinary fill pass diverter valves rely on soft elastomer seals, which are exposed to blast abrasion causing them to erode and tear away during service.

- Rotating tunnel style diverters typically have seals that are exposed to excessive wear upon actuation making them prone to seizing and binding due to material build-up between the housing and plug. The fill pass diverter has live loaded wear compensating seals which are self-cleaning on each actuation.

- The fill pass allows the convenience of continuous conveying, without having to shut down the conveying line to shift ports. It is also stackable to accommodate multiple conveying lines.