Difference between revisions of "Flight Conveyors"

(Created page with "Category:Belt Conveying{{Knoppen}} <noinclude><!------------------------------------------------ * READ THIS FIRST * Only edit this page if you can improve the content. * Im...") |

|||

| Line 7: | Line 7: | ||

* Please start editing this page after the /noinclude | * Please start editing this page after the /noinclude | ||

* -------------------------------------------------></noinclude> | * -------------------------------------------------></noinclude> | ||

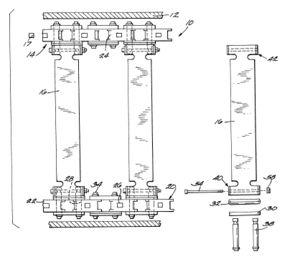

[[File:Flight-conveyor.jpg|thumb|right|Flight Conveyors]] | |||

[[File:Chain-and-flight-conveyor.jpg|thumb|right|Chain and Flight Conveyors]] | |||

'''Flight Conveyors''' are conveyors in which paddles, attached to single or double strands of chain, drag or push pulverized or granulated solid materials along a trough. Also known as drag conveyor. | |||

Flight conveyors are simple in design, sturdily constructed of durable materials, and provide an efficient, economical and dependable conveying medium, reflecting the benefits of sound engineering experience.Flight conveyors employ scraper plates or flights, carried by one or two strands of chain, to push coal or other material along in troughs, which may be inclined up to 45 degrees. Discharge may be at the end or at intermediate points through gates. | |||

Flight conveyors have scrapers, or flights, mounted at intervals perpendicular to the direction of travel on endless power-driven chains operating within a trough. Bulk materials such as sawdust, sand, gravel, coal, and chemicals may be pushed along the trough. | |||

Operation Flight Conveyor is very simple. Ash falls from the boiler into a water-filled, upper trough that quenches and cools the ash. Chains and flights move the ash along the horizontal trough and up a dewatering ramp. At the top of the ramp, the ash falls through a discharge chute into a concrete bunker, where it can be loaded into trucks for final disposal. The flights continue through the lower (dry) chamber to the rear of the conveyor and then return to the upper trough. | |||

Latest revision as of 22:08, 19 August 2012

Flight Conveyors are conveyors in which paddles, attached to single or double strands of chain, drag or push pulverized or granulated solid materials along a trough. Also known as drag conveyor. Flight conveyors are simple in design, sturdily constructed of durable materials, and provide an efficient, economical and dependable conveying medium, reflecting the benefits of sound engineering experience.Flight conveyors employ scraper plates or flights, carried by one or two strands of chain, to push coal or other material along in troughs, which may be inclined up to 45 degrees. Discharge may be at the end or at intermediate points through gates.

Flight conveyors have scrapers, or flights, mounted at intervals perpendicular to the direction of travel on endless power-driven chains operating within a trough. Bulk materials such as sawdust, sand, gravel, coal, and chemicals may be pushed along the trough.

Operation Flight Conveyor is very simple. Ash falls from the boiler into a water-filled, upper trough that quenches and cools the ash. Chains and flights move the ash along the horizontal trough and up a dewatering ramp. At the top of the ramp, the ash falls through a discharge chute into a concrete bunker, where it can be loaded into trucks for final disposal. The flights continue through the lower (dry) chamber to the rear of the conveyor and then return to the upper trough.