Difference between revisions of "Reversible Impactors"

(Created page with "Category:Particle Size Reduction{{Knoppen}} <noinclude><!------------------------------------------------ * READ THIS FIRST * Only edit this page if you can improve the c...") |

PurplePen19 (talk | contribs) |

||

| Line 5: | Line 5: | ||

* Please do not edit the sponsored link on the top right corner. . | * Please do not edit the sponsored link on the top right corner. . | ||

* Please start editing this page after the /noinclude | * Please start editing this page after the /noinclude | ||

* -------------------------------------------------></noinclude> | * -------------------------------------------------></noinclude> | ||

[[File:Reversible Impactors_1.jpg|thumb|200px|right|Reversible Impactors]] | |||

[[File:Reversible Impactors_2.jpg|thumb|200px|right|Reversible Impactors Diagram]] | |||

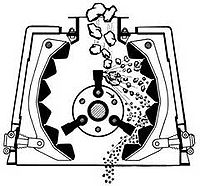

'''Reversible Impactors''' are used for secondary and tertiary crushing, and occasionally for primary crushing. They reduce limestone, potash, trona, cement rock, gypsum, chemicals, lime, lightweight aggregate, sand molds, salt cake, brick, ceramics and other materials. Offered in numerous sizes, capacities and reduction ratios, these crushers can be easily adjusted to vary output size or to compensate for wear. | |||

Reversible Impactor incorporates two crushing chambers on opposite sides of the rotor assembly. When operators reverse the direction of rotor rotation, wear is distributed between the two chambers. This also allows opposing hammer faces to wear evenly and maintain a uniform profile, enabling them to impart solid, direct impacts to the material. Inherently eliminated is the time consuming practice of taking the unit out of service to manually turn all of the hammers as required by one-way (non-reversible) impactors. | |||

==Common Features== | |||

Compact Size | |||

Rugged Construction | |||

High Performance | |||

Efficient Operation | |||

==Video== | |||

<youtube>mSDkRv9diLw</youtube> | |||

Latest revision as of 08:46, 15 October 2012

Reversible Impactors are used for secondary and tertiary crushing, and occasionally for primary crushing. They reduce limestone, potash, trona, cement rock, gypsum, chemicals, lime, lightweight aggregate, sand molds, salt cake, brick, ceramics and other materials. Offered in numerous sizes, capacities and reduction ratios, these crushers can be easily adjusted to vary output size or to compensate for wear.

Reversible Impactor incorporates two crushing chambers on opposite sides of the rotor assembly. When operators reverse the direction of rotor rotation, wear is distributed between the two chambers. This also allows opposing hammer faces to wear evenly and maintain a uniform profile, enabling them to impart solid, direct impacts to the material. Inherently eliminated is the time consuming practice of taking the unit out of service to manually turn all of the hammers as required by one-way (non-reversible) impactors.

Common Features

Compact Size Rugged Construction High Performance

Efficient Operation

Video