Super Thin Mills

Super Thin Mills are equipment which produces thin powder and super thin powder. It is applicable to non-flammable and non-explosive materials with hardness less than 6, such as calcite, chalk, limestone, dolomite, kaolin, bentonite, talcum, talc, magnesite, illite, pyrophyllite, vermiculite, sepiolite,etc.

Advantages

High efficiency and capacity and low cost. Environmental protection of low pollution and noise. Advanced speed control device and high quality grinding media. Large range of fineness adjusting. Finished size can reach to d97≤5μm. No rolling bearing and screw (in the grinding cavity) to avoid damage machine.

Parts

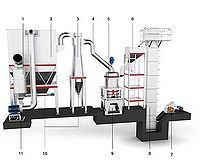

Super thin grinding mill consists of mainunit, deceleration machine, blower, hammer crusher, dustpan elevator, electro-magnetic vibrating feeder, impulse dust cleaner, piping device, cyclone collector device, classifier, high-pressure motor and muffler.

Applications

Super Thin Mill is designed to get fine and ultrafine powder. It is mainly used to powder processing of mineral products in industries of metallurgy, construction, chemistry, Fertilizer and mining etc. The ultrafine grinding mill process materials with middle and low hardness, moisture below 6%, and the material should be non-explosive and non-flammable, such as limestone, calcite, graphite, dolomite, talc, mica, magnesium, bentonite, kaolin, sepiolite, barites, gypsum, alunite, fluorite, illite, phosphate rock, kalium ore, vermiculite, attapulgite, diatoms, diatomite, etc.

Video