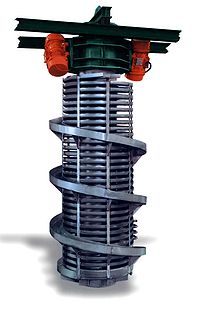

Vibratory Elevators

Vibrating elevators are designed to elevate a variety of bulk solids without spilling or jamming parts. Commonly, this kind of elevator is similar to Spiral Elevators. Vibrating Spiral Elevator with controlled velocity descent trough prevents damage to fragile parts as they enter system.

Application Processes

Product fed from the top onto the deep-angled descent trough travels gently down the trough, slowed by the upward action of the Vibrating Spiral Elevator. The bottom flights are either submerged in a solution for cleaning or in water for quenching applications. High density, low angle ascent troughs elevate the material and provide long retention times for drying as product emerges from the bath. For cleaning applications, steam jacketing heats the submerged troughs to enhance the efficiency of the cleaning solution. High density, spiral flighting design is ideal for applications with limited floor space.

Common Features

- stainless steel flights;

- adjustable angles

- corrosion resistant

- heavy-duty

- rubber isolation springs.

- Water-proof vibrating motors with adjustable eccentric weights provide retention control, and overhead isolation minimizes vibration transmission.

Videos