Bead Mills

Bead Mills are one of the many technologies used for grinding, lysing and homogenization of laboratory samples. Bead Mills are typically used for samples that are difficult to disrupt with standard mechanical laboratory homogenizers. These sample types include tumor, heart, e-coli, yeast, bone, skin, cartilage, spores, seeds and soil. Bead Mills can also be used to extract nucleic acids and proteins and can be used with difficult to process cells such as cyanobacteria, mycobacteria, and microalgae.

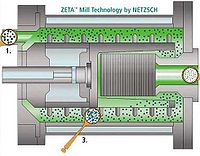

Bead Mills employ very small glass, ceramic or steel beads. These beads are placed in a vessel along with the sample media. The vessel, beads and sample are vigorously agitated by shaking or stirring. Disruption of the sample occurs as the beads collide rapidly with the cells. A combination of the grinding beads and rotational effect produces a faster, more reliably effective lysing process for biological samples. Typically, a higher volume ratio of beads to cells produces a faster rate of cell disruption. After the processing cycle is complete, the beads settle by gravity in the vessel and the resulting homogenate is easily removed by pipette.

Bead Mills are relatively cross-contamination free because of the disposable beads and sample tubes they employ. Most shaking-type Bead Mills are restricted to sample sizes of 3.0mL or less. However, several samples can be processed at a time. Heat generation can be a problem with Bead Mills, but many of today’s Bead Mill units are available with optional cooling features and accessories.

Process

Circulation Grinding is a cost-effective solution for grinding large quantities of material as it allows for a lower cost capital investment in equipment and grinding media than with many other grinding equipment options.

Additional benefits of circulation grinding include a narrower particle size distribution, the ability to continuously monitor the slurry, add ingredients to the premix tank at any time during the grinding cycle and control temperature more precisely since the slurry spends only 15-25 seconds in the grinding chamber.

Video