Micronizers

Jump to navigation

Jump to search

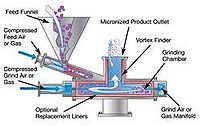

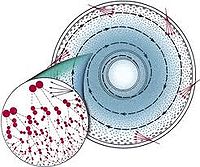

Micronizers are Jet Mills that are used in employing compressed air or gas to produce particles less than one micron. Inside the Micronizer, precisely aligned jets create a vortex. Material is fed into this vortex along an engineered tangent circle and accelerates.

High-speed rotation subjects the material to particle-on-particle impact, creating increasingly smaller fines. While centrifugal force drives large particles toward the perimeter, fine particles move toward the center where they exit through the vortex finder.

Advantages

- Narrow particle size distribution

- Spherical uniform particle shape

- No heat buildup

- No product contamination

- Low maintenance

- Simple operation

- Sanitary design requires no tools

Applications

- Agricultural chemicals

- Carbon Black

- Ceramics

- Chemicals

- Cosmetics

- Deagglomeration

- Food Products

- Heat Sensitive Materials

- Minerals and metals

- Pharmaceutical

- Pigments

- Powdered milk

- Precious metals

- Propellants

- Resins

- Silica Sand

- Titanium Dioxide

- Toner

Video